Dryer design tools

-

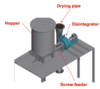

The function of a flash dryer system is to dry powdered products such as cassava flour and starch. This tool calculates key parameters of the flash dryer system based on the characteristics of the product to dry.

The function of a flash dryer system is to dry powdered products such as cassava flour and starch. This tool calculates key parameters of the flash dryer system based on the characteristics of the product to dry. -

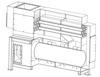

The feeding system is the part of the flash dryer that bring the wet product into the drying pipe, and breaks the product into fine particles at the same time. This tool calculates the dimensions of a screw conveyer according to the product flow rate you want to feed to the flash dryer.

The feeding system is the part of the flash dryer that bring the wet product into the drying pipe, and breaks the product into fine particles at the same time. This tool calculates the dimensions of a screw conveyer according to the product flow rate you want to feed to the flash dryer. -

The cyclone is the component at the end of the drying pipe, that separates the dry product from the wet air. This tool calculates the dimensions of a cyclone.

The cyclone is the component at the end of the drying pipe, that separates the dry product from the wet air. This tool calculates the dimensions of a cyclone. -

Pressure drop calculations to evaluate the required power of the blower/fan

Blowers are very common devices used to generate an air flow by creating a difference of pressure. The following tool calculates the pressure drop of a drying system to determine the efficiency of the process.

Blowers are very common devices used to generate an air flow by creating a difference of pressure. The following tool calculates the pressure drop of a drying system to determine the efficiency of the process. -

The heat exchanger is a component of the drying system that is generally used for fuels such as diesel, wood, and others. In view of the high contamination that is generated in its combustion, the hot air could not be in direct contact with the final product (cassava starch/flour). Therefore, the heat exchanger allows "clean" and hot air to enter the flash dryer without being in direct contact with the diesel/wood combustion. This tool calculates the main design parameters of a hot air generator to supply hot air to a flash dryer.

The heat exchanger is a component of the drying system that is generally used for fuels such as diesel, wood, and others. In view of the high contamination that is generated in its combustion, the hot air could not be in direct contact with the final product (cassava starch/flour). Therefore, the heat exchanger allows "clean" and hot air to enter the flash dryer without being in direct contact with the diesel/wood combustion. This tool calculates the main design parameters of a hot air generator to supply hot air to a flash dryer.